DekaMarkt currently has 79 stores and recently announced that it had reached agreement on the acquisition of 19 Deen stores, after which DekaMarkt will have almost 100 stores in the Netherlands. DekaMarkt's fast growing delivery service is managed from the Digital Fulfilment Center in Velsen-Noord.

Outsourcing not an option

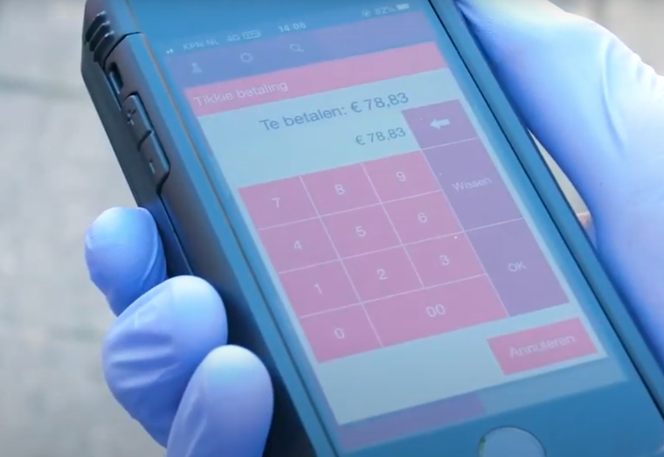

DekaMarkt does the home delivery of groceries with its own vans and its own staff. "Outsourcing the fulfillment process and the last mile is not an option for DekaMarkt," states Thijs. "The online food retail supply chain is relatively complex. Items have to be stored, picked and transported at different temperatures, there is a limited shelf life for items and it must be possible to collect the packaging at the door and deduct it from the amount owed; this is simply a bridge too far for logistics service providers.

This will change, food is a market with enormous potential, but for the time being food retailers like us have to organize the fulfilment process, including the last mile, themselves. The advantage is that we have complete control over the process and the moment of delivery to the customer. That very moment is a very important touch point that has a major influence on the satisfaction and loyalty of our customers.”

Online retail in a split

Fueled by the corona crisis, the market for online groceries has virtually exploded and food retailers such as DekaMarkt have to pull out all the stops to steer this shift in logistics flows in the right direction. “The main challenge is to make it a future-proof business model,” says Thijs candidly. “Instead of customers coming to the store and doing their shopping themselves, we now do this for them; we collect the groceries, pack them and bring them home. There is a considerable cost involved, but the willingness among consumers to pay for this is nil. In addition, the market expects us to deliver faster and faster and to expand our range further. This is a split that we and other food retailers are in. I am convinced that there are solutions, but they are still relatively far away in time for several reasons.”